The above table mainly applies to the list of unemployed and typical materials:

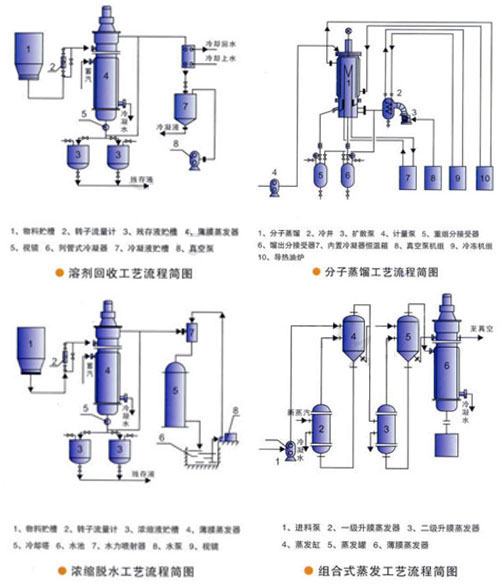

Thin film evaporators can be used for chemical unit operations such as material concentration, degassing, desolvation (solvent recovery), purification, etc. The following processes are available for reference:

1. Material concentration (evaporation of moisture) is shown in Figure (8)

2. Desolvation or purification as shown in Figure (9)

3. As the reboiler of the distillation tower, see Figure (10A, B)

4. Composed of a multi effect evaporator with a tubular evaporator, as shown in Figure (11)

5. Compose a multi-stage distillation with a short range still, as shown in Figure (12)

6、 Selection instructions for thin film evaporator

The selection of thin film evaporators should comprehensively consider various factors, which are interrelated and generally need to consider:

1. Determination of evaporation area:

▲ Calculation of evaporation capacity: Calculate the evaporation capacity per unit time (Kg/h) based on the processing capacity and inlet/outlet concentration;

Estimate the evaporation intensity of the evaporator based on the viscosity, concentration, and evaporation temperature of the material;

Consider a certain amount of surplus and calculate the required evaporation area.

2. Determination of vacuum degree

The acquisition of vacuum degree is at the cost of energy consumption, as long as the evaporation requirements are met, there is no need to require too high vacuum degree;

Estimate the vacuum degree at this evaporation temperature based on the thermal sensitivity of the material;

▲ Consider the possibility of leakage and the frictional resistance of secondary steam to determine the required vacuum level;

3. Determination of scraper form and material

▲ According to the physical and chemical properties of materials such as viscosity, crystallization tendency, foam, etc., select the appropriate scraper form, and consider the evaporation temperature to determine the appropriate material;

4. Determination of thermal medium

Based on the required evaporation temperature and heat consumption, determine the use of a suitable thermal medium such as steam, hot water, or thermal oil.

5. Determination of evaporator material selection

6. Selection and determination of motor explosion-proof performance

Our factory has accumulated years of practical application experience and will assist customers in making appropriate product selection without reservation.

Note: "We have a small prototype and welcome customers to come and test it““

|